Premier Custom Corporate Gift Box Supplier for USA Enterprises

We engineer and manufacture high-precision rigid gift boxes specifically for American corporate gifting campaigns.

Key Decision Data

- Minimum Order Quantity (MOQ)500 Units (Strict minimum for custom rigid setups)

- Typical Lead Time35-45 Days (Production + DDP Sea Freight to Door)

- Customization ScopeFull-bleed print, Foil stamping, Spot UV, Custom EVA/Pulp inserts

Check Project Feasibility

Confirm if our capabilities align with your project scope before proceeding to formal quoting.

Why Procurement Teams Partner With Us

We address the specific friction points found in cross-border packaging procurement.

Supply Chain Control

We don't just broker; we manage the raw material sourcing and assembly. This gives you visibility and control over paper quality and board density, preventing "quality fade" in repeat orders.

Brand Consistency

Our print facilities are G7 Master Qualified. We ensure your corporate Pantone colors are reproduced accurately across different substrates, maintaining brand integrity.

DDP Logistics Expertise

We handle all US Customs clearance, duties, and tariffs. The price we quote is the price you pay delivered to your office or fulfillment center, with no surprise fees.

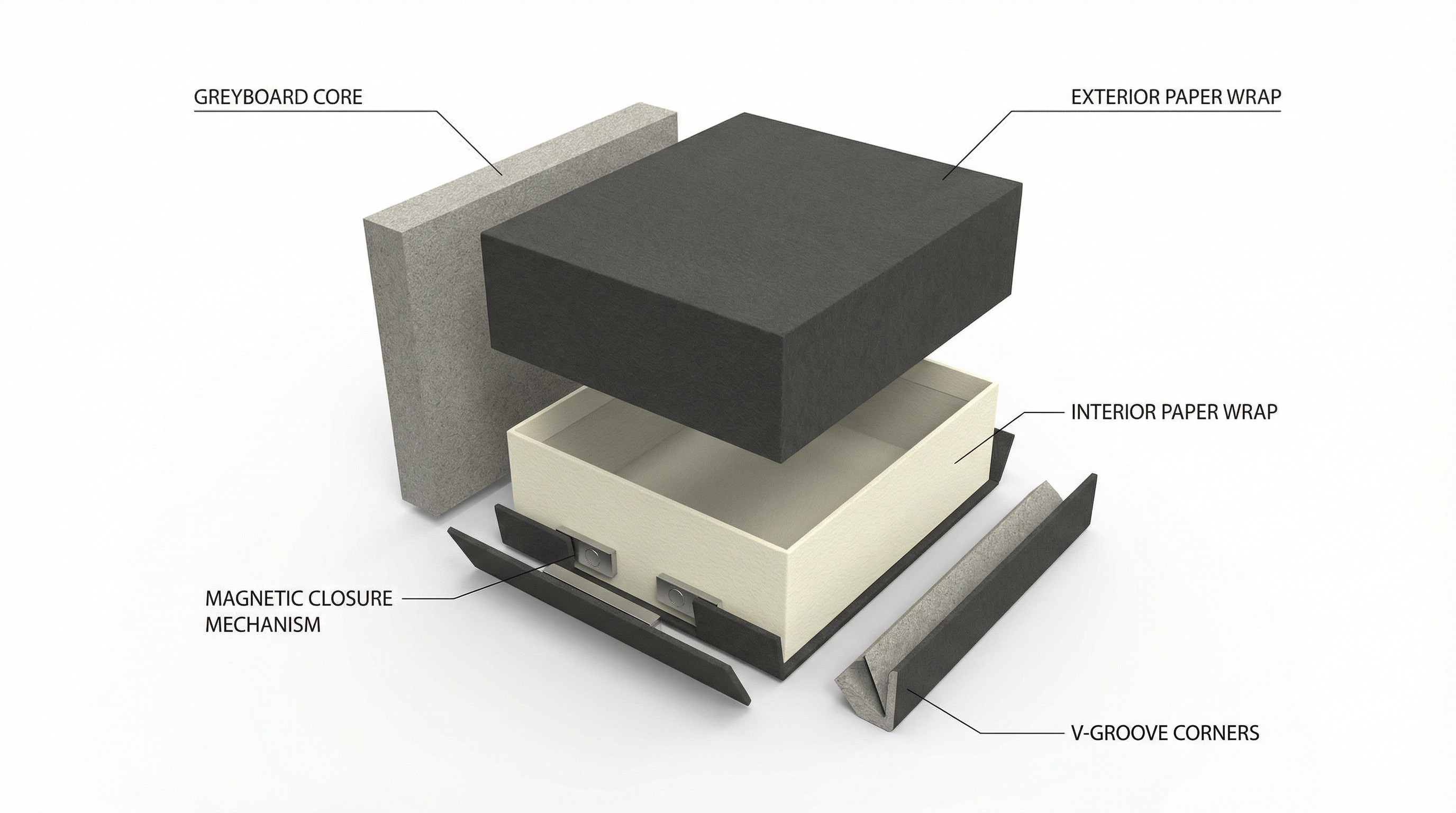

Exploded view of our standard rigid box construction

Engineered for Mass Production Stability

We focus on specifications that balance premium aesthetics with manufacturing scalability.

Core Material

High-density Greyboard (1200gsm - 1800gsm). Selected for optimal stiffness to withstand US domestic shipping networks without crushing.

Wrap Options

157gsm Art Paper is our standard for best print definition. Available with Soft-touch, Matte, or Anti-scratch lamination.

Structural Styles

Magnetic Closure (Book style), Lid-and-Base (2-piece), and Drawer styles. All corners are V-grooved for sharp 90-degree edges.

Inserts

Custom die-cut High Density EVA foam or molded paper pulp. We engineer the cavity to hold your specific items securely.

Production Workflow (USA Context)

1. Requirement Alignment

We confirm your budget, timeline, and unboxing goals. We advise on feasibility to prevent over-engineering.

2. Structural Sampling

We produce a plain white dummy sample. You test this physically with your products to verify fit and protection.

3. Pre-production Proof

Once structure is approved, we print a full-color sample. This is the "Golden Sample" for color and finish sign-off.

4. Mass Production & QC

Automated wrapping and manual assembly. We perform AQL inspections to ensure the 500th box looks exactly like the 1st.

5. Logistics & Delivery

We manage the sea/air freight. Goods are cleared through US Customs and delivered via truck to your specified location.

USA Compliance Focus: Toxics in Packaging

Many US states have strict laws (TPCH) regarding heavy metals in packaging materials (lead, cadmium, etc.). Cheaply sourced dyes and adhesives often fail these tests, leading to potential recalls or fines. We exclusively use compliant, tested materials safe for the US market.

Common Corporate Scenarios

Employee Onboarding

High-quality welcome kits that improve retention. Requires durable boxes for shipping to remote employees.

VIP Client Gifting

Luxury "soft-touch" finishes for C-suite recipients. Focus on tactile experience and flawless details.

Event Swag Boxes

Bulk production for conferences. Strict deadlines where "late" means "useless".

Influencer Seeding

Photogenic packaging designed specifically for "unboxing" videos on social media.

Proven Experience

Serving US Corporate Clients

Boxes Delivered to North America

DDP Delivery Success Rate

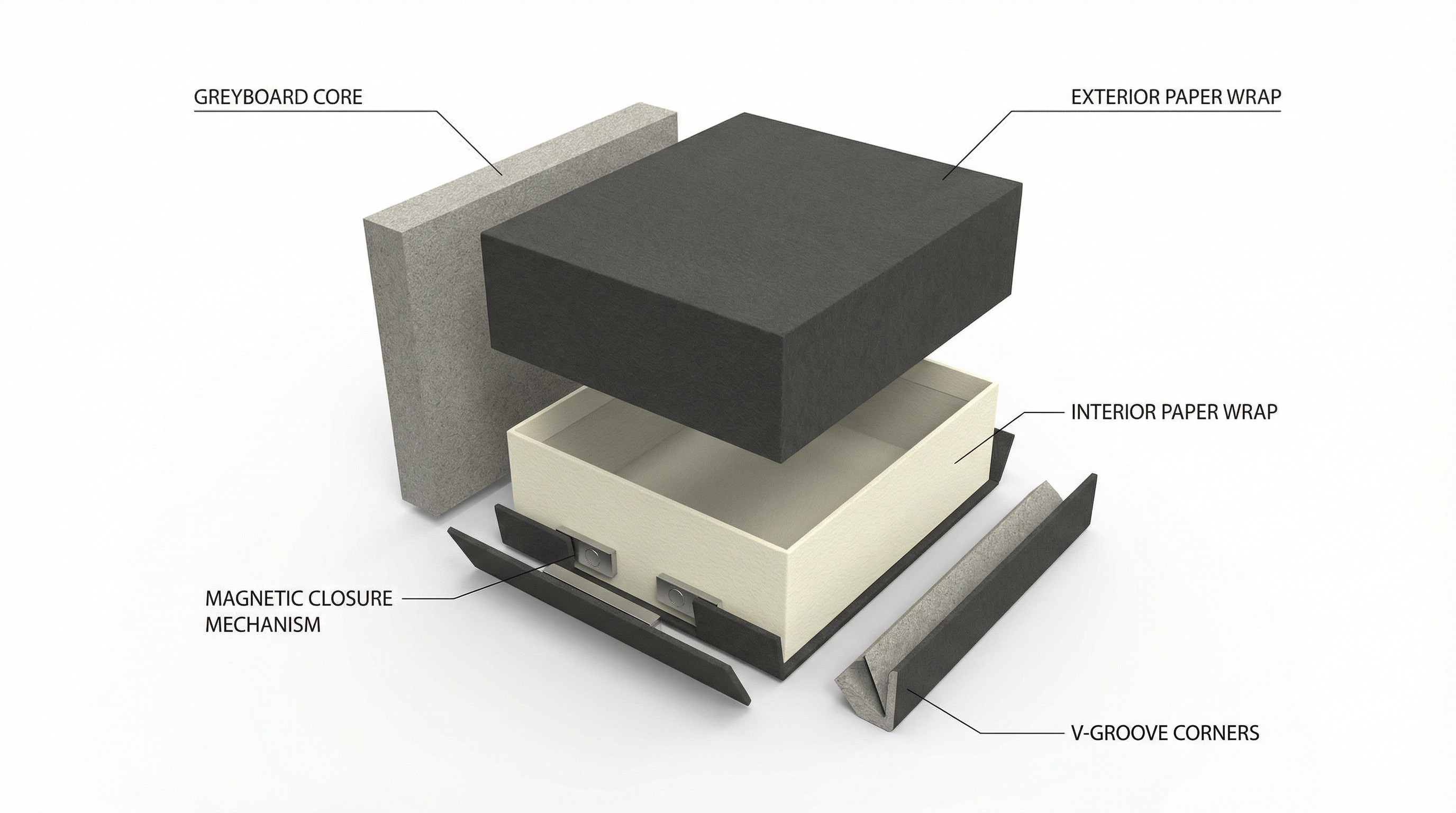

Detail of our foil stamping capability

Ready to Verify Your Project?

When to submit a request:

We recommend submitting this form only when you have a rough estimate of your quantity and timeline.

If you are still in the early brainstorming phase without these details, we suggest browsing our catalogue first. Submitting with concrete details allows our engineers to provide a meaningful feasibility assessment rather than a generic estimate.